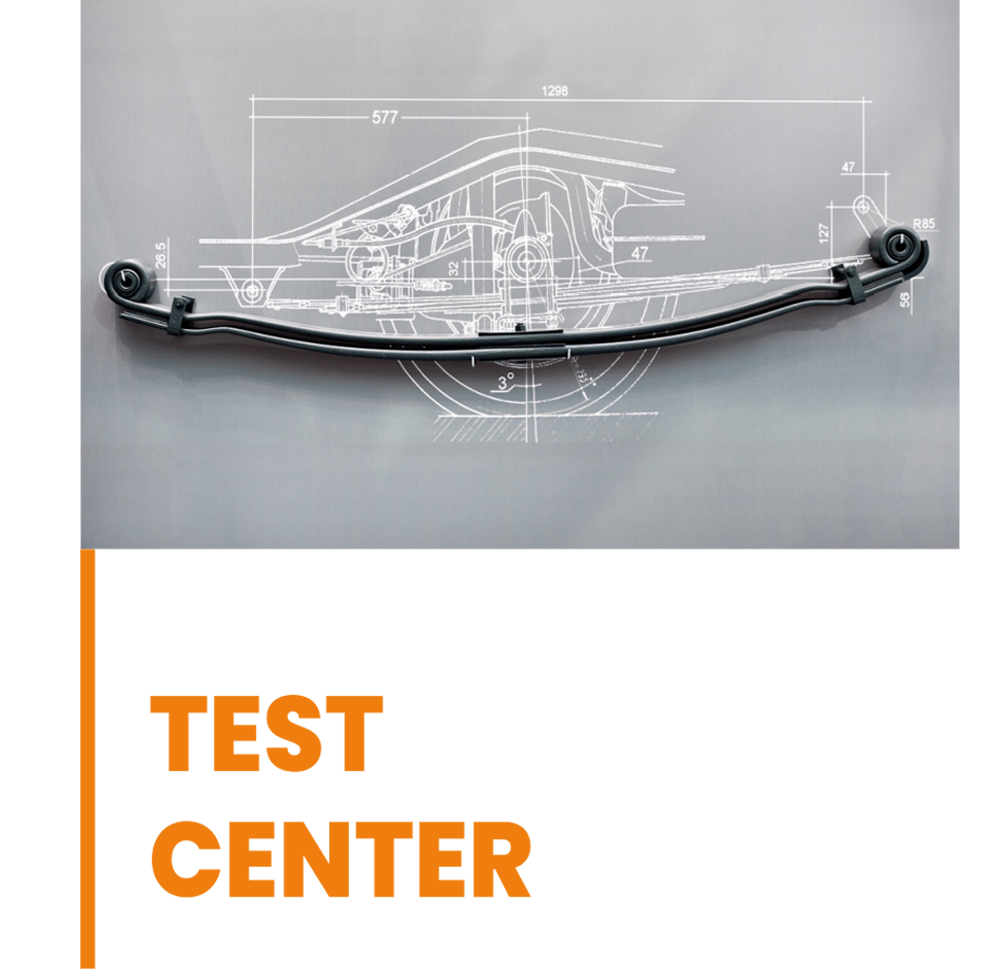

We are proud to have opportunities beyond geographical and technological boundaries at the Olgun Celik Test Centre, which we decided to invest in in 2015, based on the fact that immeasurable quality cannot be managed.

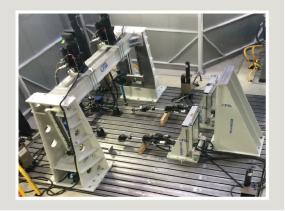

We are proud to be able to meet the verification demands of all our customers in the global automotive industry within our own body thanks to our advanced technology test system, which allows all forces on the vehicle components to be applied without any loss during the use of road vehicles, our advanced data collection systems that measure the effects on the components, and our seismic base surfaces that separate the system from side effects.

Our test centre, which we learned as we developed and developed even more as we learned, has brought a great competitive advantage to our company by helping us to illuminate our way with the numerous projects it has realized so far. We are happy to become one of the leading test centres in the European automotive industry and a centre of excellence that provides testing services to other organizations besides its own needs, thanks to our investments that we increase every year with this awareness.